Full vs Half Pedestal Wash Basin: Smart Buying Guide

09 January, 2026

Connect With Our Team

When selecting rope for your next project, the choice between rope twisted and braided rope construction can make or break your success. Whether you are rigging a boat dock, setting camp, or performing a heavy-duty lifting operation, being familiar with two of the most basic rope designs will save you time, money, and potential headaches.

The difference between twisted and braided rope goes far beyond appearance. Your selection determines what it will be like in terms of strength and durability, cost and convenience. Twisted ropes, with their traditional three-strand design, offer excellent grip and splicing capabilities, while braided ropes provide superior strength-to-weight ratios and smoother handling through pulleys and hardware.

This comprehensive guide examines both rope twisted and braided rope constructions in detail, helping you make informed decisions based on your specific applications, budget, and performance requirements. We look at theoretical material options, real-life performance characteristics, and practice to use to select your ideal rope whenever you need one.

The 3 strand twist structure construction rope has unique traits. The helical design offers superb grip when handling it and means there is plenty of natural water and debris shedding channels to rid it of unwanted stayers. This construction method works exceptionally well with various materials, making twisted polypropylene rope, twisted polyester rope, and twisted nylon rope popular choices across different industries.

Commercial Rope: General-purpose twisted rope designed for industrial and commercial applications. Commercial rope can be made of many materials, and ranges vary in their diameters, which makes them dependable in daily activities such as securing freight, construction, and general rigging activities.

HDPE Monofilament: HDPE monofilament rope is extremely resistant to a wide range of chemicals and strong. The single-filament format of this product in the twisted version is extremely abrasion resistant, which makes it ideal in hard industry applications, such as in harsh industrial transports, as well as marine applications where chemical treatments are common.

PP Danline Rope: Polypropylene danline rope represents a premium twisted rope option with enhanced UV stabilization and superior strength characteristics. The danline construction process results in rope with great knot holding capabilities, where it is used in the fishing, marine, and agricultural industries.

Telstra Rope: A specialized twisted rope variant known for its high-visibility colors and enhanced durability. Telstra is also often made in bright orange or yellow, such as when the rope is used in safety courses, and in the case of being constructed in a twist, it can be reliable and competitive in the telecommunications and utility industries and safety applications.

Polypropylene: Lightweight, floats on water and cannot be degraded by the sun. Yellow polypropylene rope is particularly popular for marine and outdoor applications due to its high visibility and weather resistance.

Polyester: This material has a great wet strength retention, low stretch rate, and an outstanding UV resistance. Twisted polyester rope maintains its properties in harsh environmental conditions.

Nylon: Offers the maximum strength and the best shock absorption as a result of its inherent elasticity. Nevertheless, nylon is a fiber-weaker when wet and represents a cost-losing material, compared to polypropylene.

The twisted construction method creates rope with predictable behavior under load. When the tension is high, the strands automatically get tensed across the rope cross-sectionally, which reduces the stress in the rope. This characteristic makes twisted rope reliable for applications where consistent performance is crucial. If you are looking for durable and high-quality twisted ropes, Grepl Group is a trusted manufacturer and supplier you can rely on. Whenever you want to purchase ropes used in industries, marine or in general application, you can make contact with them at any time you want.

Braided rope construction weaves multiple strands or yarns together in complex patterns, creating rope with fundamentally different characteristics than twisted alternatives. Compared to the basic three-strand twist, it is possible to use many more individual strands in a complex pattern in braided construction.

Hollow Braided: It is characterised by a tubular construction without a core. The ropes are not as heavy to carry, nor are they rigid, though they also have low strength ratings. They are best suited to lightweight applications where flexibility is of higher importance than the resulting strength.

Solid Braided: Made up of a braided core surrounded by a braided outer jacket. This allows great strength and retains flexibility and easy handling characteristics.

Double Braided (Braid-on-Braid): A rope with both cover and core laid braided, with each contributing to the strength of the rope. It is made of high-quality construction, which has the most optimal combination of strength, handling and durability.

Kernmantle: Features a parallel fiber core (kern) surrounded by a woven sheath (mantle). While technically different from traditional braiding, kernmantle construction shares many characteristics with braided ropes.

Braided polyester rope and braided polypropylene represent the most common material combinations. The braided construction distributes load across many more fiber contact points than twisted rope, typically resulting in higher strength ratings for equivalent diameters.

The smooth exterior of braided rope runs exceptionally well through blocks, pulleys, and hardware. This characteristic makes braided rope preferred for applications involving mechanical advantage systems or frequent movement through hardware.

| Feature | Twisted Rope | Braided Rope |

|---|---|---|

| Construction | 3-strand helical twist | Multiple strands woven together |

| Strength (Same Diameter) | Lower working load limit | 15-25% higher strength rating |

| Grip & Handling | Excellent texture, natural grip channels | Smooth surface, may be slippery when wet |

| Flexibility | Good flexibility, maintains shape | Excellent flexibility, very pliable |

| Stretch Characteristics | Material-dependent, predictable elongation | Generally lower stretch, precise load control |

| Splicing Ease | Excellent - traditional splice techniques | Difficult - requires specialized methods |

| Knot Holding | Superior grip, knots hold securely | Good but may require careful knot selection |

| Pulley Performance | Higher friction, more wear | Smooth operation, reduced friction |

| Cost | Lower initial cost | Higher upfront investment |

| Inspection | Easy visual inspection of strands | Harder to detect internal damage |

| Failure Mode | Gradual with visible warning signs | Can fail suddenly without warning |

| Water Shedding | Natural channels shed water/debris | Smooth surface may retain moisture |

| UV Resistance | Material-dependent | Material-dependent |

| Abrasion Resistance | Good surface texture protection | Varies by braid type and tightness |

Braided rope generally offers superior strength ratings compared to twisted rope of equivalent diameter and material. The braided in multiple fiber contact points spread the load better, and manufacturers can use this to have high working load limits. A typical braided polyester rope may offer 15-25% higher strength than an equivalent twisted polyester rope.

However, twisted rope provides more predictable failure modes. When twisted rope approaches its breaking point, individual strands typically show visible wear or fraying, providing warning signs. Braided rope can fail more suddenly, particularly if the outer braid sustains damage that isn't immediately visible.

For long-term durability, twisted rope has advantages in certain environments. The untwisted nature of the construction lends itself to prevents debris build-up, as well as the three-strand configuration allows convenient assessment of individual strand integrity.

Twisted rope offers a distinctive tactile experience with its textured surface providing excellent grip for bare hands. The spiral shape leaves natural gripping channels, which will not clog when wet. This characteristic makes twisted poly rope popular for applications where manual handling is frequent.

Braided rope provides smoother handling with less friction against skin and clothing. The woven exterior slides through hardware more easily, so it is desirable when there is pulley or winch work involved. However, braided rope can be more slippery when wet, potentially requiring gloves for secure handling.

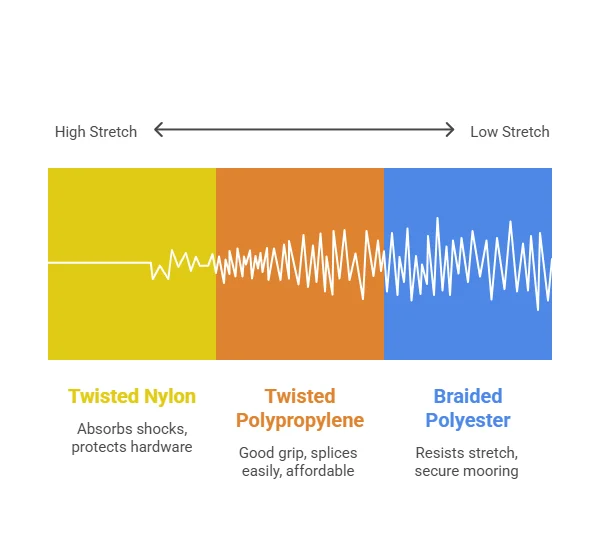

The effect of the choice of material on stretch characteristics is greater than the effect of the construction method, although some patterns play out. Twisted nylon rope serves as an excellent shock absorber, partly because of the characteristics of the material and partly because of the helical turns that permit those individual strands to stretch.

A braided construction normally makes up rope with less stretchiness, especially with polyester varieties. Braided polyester rope often exhibits minimal stretch under working loads, making it preferred for applications requiring precise load control or minimal elongation.

Twisted rope excels in splicing applications. The 3 strand twist structure fabrication enables conventional splice techniques that provide strong, permanent connections without the use of hardware. Eye splices in twisted rope can retain 85-95% of the rope's original strength when properly executed.

Braided rope presents challenges for traditional splicing but accepts knots readily. The smooth surface of braided rope requires careful knot selection, as some knots may slip more easily than with twisted rope. However, braided rope's flexibility often allows for more compact knot tying in confined spaces.

Twisted rope generally costs less than braided rope of equivalent material and diameter. This difference in cost is caused by the simpler process of manufacturing and the savings in material use. Twisted polypropylene rope represents one of the most economical rope options available.

Braided rope's higher initial cost often balances against longer service life in demanding applications. The high strength and smooth handling performance are reasons enough to pay premium costs in professional use or high-use applications.

For general outdoor applications, yellow polypropylene rope in twisted construction offers excellent value. The shiny color gives good visibility for safety, and the material is polypropylene, which does not absorb water or become vulnerable to UV. Twisted poly rope handles well in all weather conditions and remains affordable for large quantity purchases.

Camping, landscaping, and general tie-down applications benefit from twisted rope's grip characteristics and splicing capability. The rugged finish allows it to be handled confidently even when your hands are wet and/or dirty.

The variability of each type of construction has unique strengths best demonstrated in marine settings. Twisted nylon rope offers great shock-absorbing capabilities to withstand wave action and movement of the tides in anchoring endeavors. The elastic is to protect both anchor hardware and the boat against sudden jumps in loads.

Docking applications often favor braided rope for its smooth handling through cleats and hardware. Braided polyester rope resists stretch while maintaining strength when wet, providing secure mooring with minimal adjustment needs.

The rigging that is used to raise it can take advantage of the smooth-running properties of the braided construction through blocks and pulleys. This minimized friction enhances mechanical advantage and minimizes wear on the rope and hardware.

Traditional camping applications often utilize twisted rope for its versatility and repairability. The specifically treated, though limited, tarred bank line shows how twisted construction also admits the addition of any process to improve certain characteristics.

Braided rope works well for applications requiring frequent setup and breakdown, such as tent guy-lines or bear bag suspension systems. The comfortable handling speeds the deployment process and the trifold knotting takes up less pack space

Professional rope access involves rope that is made and designed specifically to meet life-safety applications. Although this guide will concentrate on general-purpose rope, it is important to state that climbing and arborist work require the same level of appropriate certified rope that meets specific safety guidelines.

When operating under non-life-safety conditions, tree work, or rigging use requirements, braided construction can have a benefit in handling and strength due to the hardware. Any life-safety rope applications should always be consulted by the safety professionals and well-certified equipment should be used.

Twisted rope is made by twisting strands, while braided rope is woven in a crisscross pattern, making it smoother and stronger.

Braided rope is stronger and distributes load more evenly than twisted rope.

It’s good for tying, splicing, light-duty tasks, and decorative projects.

Best for climbing, boating, towing, camping, and heavy-duty outdoor use.

Braided rope, as it resists UV, water, and abrasion better than twisted rope.

Twisted rope is easier to knot and splice, while braided rope holds knots tighter.

Yes, twisted rope stretches more; braided rope has minimal stretch.

Braided rope, since it handles sun, saltwater, and moisture better.

Yes, braided rope costs more but lasts longer.

Choose twisted for light, low-cost tasks; braided for strength and durability.

Choosing between twisted and braided rope ultimately depends on your specific requirements, budget, and application priorities. Twisted rope offers excellent value, superior grip, easy splicing, and predictable performance characteristics. These features are optimal in extensive outdoor applications or where the product is handled and used frequently, or where low cost is of paramount concern.

Explore Durable Rope Collection

Braided rope justifies its higher cost through superior strength ratings, smooth operation through hardware, and excellent handling characteristics. Edinger's professional applications, high load, or any purpose requiring frequent movement through pulleys and blocks and blocks is best served through braided construction.

Choose Twisted Rope for: General outdoor use, hand-held applications, splicing requirements, budget-conscious projects, and situations requiring maximum grip

Choose Braided Rope for: High-strength applications, pulley systems, professional use, situations requiring minimal stretch, and applications prioritizing smooth handling

Think about the primary use case, weigh the comparison between the cost and performance, and do not be afraid to have both types deploy them in different applications. Investing in the correct rope for particular use pays off in work performance, safety, and enjoyment in the long run.

In all brands, care and storage increase rope life, no matter what construction is used. Check the rope regularly to check wear, store the rope correctly (so as not to be degraded by UV light), and when a rope shows signs of excessive wear or damage, retire it. With proper selection and care, both twisted and braided rope will provide years of reliable service.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to exports@greplgroup.com

|

Mr. Milanbhai +91 96871 06588 |

|

Mr. Hirenbhai +91 95373 06588 |