Full vs Half Pedestal Wash Basin: Smart Buying Guide

09 January, 2026

Connect With Our Team

Ropes are a very important part of our daily life, whether you are defending in football or bending the rifle trigger rope. With so many choices for rope, using the wrong one for helping secure loads, climbing, towing, or crafting is a matter of caution and pointlessness. There is a variety of materials and constructions that have different strengths, forms, and long lives. We will help you discover the ropes types and their characteristics, and their uses as commercial ropes, such as HDPE monofilament, PP baler twine, PP danline rope, and Telstra rope.

Key terminology is used to differentiate different rope types, and before picking a rope, one needs to know what it is adequate for.

Fibers vs. Strands vs. Braids: Ropes are fibers twisted together into strands then braided or twisted. It affects durability and flexibility.

Rope Construction

Twisted Rope: Traditional design, easy to splice, good grip, but can unravel under stress.

Braided Rope: Dynamic loads, abrasion resistant, smoother and stronger, ideal braided rope.

Of course, these basics help you to choose the right rope for whatever task you are looking to accomplish.

Natural fiber ropes are biodegradable and made from some organic materials such as cotton, jute, hemp, and coconut husk. The ropes have an excellent grip, absorb moisture, and are easy to handle. Although these have more of a traditional look and are commonly used in many different industries, they are less durable and weaker than synthetic ones. For use indoors, decorative and light duty, the natural fiber ropes are the superior choice.

Properties: Cotton ropes are soft, flexible, and easy to dye, properties make them a favorite for decorative and crafting products. They are biodegradable and non-abrasive, so they are friendly on hands and pets, making them fit for indoor use. Cotton ropes are also especially absorbent, leading to mold and mildew development if they are not stored in a dry place.

Common Uses: For this reason, cotton ropes are commonly used in macrame, pet toys, home decor, and arts and crafts. Other applications in which they are used are sash cords, stage productions, and lightweight bundling purposes.

Strength & Durability: Made from the abaca plant fibers, manila rope is known for its high tensile strength, resistance to UV rays, and great grip. This strength is one of the strongest natural fiber ropes, and due to its elasticity no matter the length of time, it would last long after one. While it absorbs moisture, mildew and rot may trouble it if it is not dried properly after exposure to water.

Best Applications: Manila ropes are best used in Marine industries, climbing, heavy duty lifting, construction works, and as a decorative material. Besides, their strength and good hand grip make them highly popular for making playground equipment, gym climbing ropes, and tug-of-war competitions.

Texture & Properties: Sisal rope is made from the agave plant and is distinguished for its rough texture, rigidity, and great durability. But first and foremost, this fiber is biodegradable, which makes it an eco-friendly fiber, but it is also notorious for shedding its fibers and disintegrating faster with higher moisture content. There you have it, Sisal has better knot holding ability than synthetic ropes and is natural resistance to pests and rodents.

Common Uses: Since it is slimmer, it is not quite as commonly used as other types of sisal, but it is used for agricultural, fencing, and gardening applications. They are rough in texture making them ideal for cat scratch posts and pet accessories. They are common in DIY projects, landscaping, and decorative purposes. Farmers use them for baling hay.

Lightweight & Water-Resistant: Made of coir ropes that are coconut husk fibers which are lightweight, tough, water resistant, and resistant to microbial attacks as well. They, of course, are suited for wet and coastal environments. Coir ropes are not as strong as manila or sisal ropes; for this reason, they are valued, however, for their sustainability and natural resilience.

Applications: Coir ropes are extensively utilized in erosion control, matting, landscaping, etc. Because they are biodegradable, they are a great choice for temporary fencing, agricultural applications, handicrafts, etc. These ropes are also used in the making of eco-friendly packaging solutions, boat ropes and fishing nets.

Man-made material natural fiber ropes are synthetic fiber ropes that are built up and made of man-made materials and give great strength, sturdiness, and opposition to environmental components compared with normal hair ropes. It doesn’t absorb moisture, thus is resistant to rot and can handle harsh weather conditions; thus is used in marine, industrial, rescue, and commercial applications. There are different kinds of synthetic ropes, which have different elasticity, UV resistance and load-bearing capacity suitable for the specific industry.

What is HDPE Rope?

HDPE (High-Density Polyethylene) monofilament rope is a very hard, strong synthetic rope constructed out of a matrix of HDPE strands. This is widely used for its excellent chemical, moisture, UV, and abrasion resistance, and it is widely used indoors as well as outdoors. HDPE monofilament rope doesn’t rot, decay, or absorb water, so unlike natural fiber ropes, HDPE monofilament rope performs well in harsh environments. At the same time, it also has an extremely lightweight yet robust structure, which makes it easily handled yet with an excellent tensile strength, which makes it a top call-out application for fishing, marine, agriculture, industrial packages and construction works.

Uses of HDPE Monofilament Rope

Fishing and marine industries due to its excellent water resistance.

Agriculture for securing crops and fencing applications.

Industrial applications such as packaging and bundling.

Used in net-making and as a substitute for traditional jute ropes.

Advantages of HDPE Monofilament Rope

Lightweight and easy to handle.

Excellent resistance to wear and tear.

UV stabilized for prolonged outdoor use.

Does not absorb water, making it ideal for marine applications.

What is PP Baler Twine?

Polypropylene (PP) baler twine is known to be very strong, lightweight, and very durable synthetic twine used in the agriculture sector. It’s made out of high-grade polypropylene fibers and is meant to resist hard tension and extreme scorching situations. PP baler twine is an easy twine to use and it is used widely in binding hay, straw, or silage into neat handling, storage, and transport bales. Mechanical testing of acrylic shows that it is UV resistant and water repellent, protecting from moisture and UV degradation in outdoor applications. Also, due to high tensile strength and knot-holding capacity, bales remain secure even in heavy loads.

Uses of PP Baler Twine

Baling hay and straw in agricultural fields.

Tying and bundling crops, plants, and other agricultural products.

Securing loads in transport and logistics.

Used in packaging industries for securing lightweight packages.

Advantages of PP Baler Twine

High tensile strength and durability.

UV resistant and weatherproof.

Lightweight and easy to handle.

Cost-effective compared to natural fiber twines.

What is PP Danline Rope?

PP Danline rope is a particular type of polypropylene (PP) rope made with very good quality Danline fibers that have great strength, flexibility, and durability. This rope has been specially built to be able to endure major loads, rough weather conditions, or continuous use, thus sticking out as being best suitable for each aggravating business and sea application. Its tensile strength is high, stretchability low, and UV, moisture and chemical resistant, meaning it has excellent longevity in the most intense environments. PP Danline rope has wide applications on account of its lightweight and floating properties, being widely used in fishing, shipping, building, agriculture.

Uses of PP Danline Rope

Marine and fishing industries for net-making and anchoring.

Construction for lifting, tying, and securing materials.

Agriculture for fencing and boundary marking.

Transportation and logistics for securing cargo.

Advantages of PP Danline Rope

High tensile strength and durability.

Resistant to chemicals, moisture, and UV rays.

Floats on water, making it ideal for marine use.

Low elongation and excellent load-bearing capacity.

What is Telstra Rope?

The Telstra rope is a high-quality rope specially designed for use in telecommunications, electrical industries and construction. It is a strong synthetic fiber rope with high quality that holds plenty of strength, durability and flexibility. Mainly utilized in cable hauling, pulling and securing of wires in telecom and power line installations, Telstra rope is manufactured with various novel features.

Due to its low stretch properties, abrasion resistance and weatherproof nature, it is well suited to outdoor and industrial applications. Furthermore, it is lightweight, easy to handle, and gives a good grip for untroubled and devoted working in outrageous conditions.

Uses of Telstra Rope

Used in telecommunication and electrical industries for cable pulling.

Construction sites for lifting and securing materials.

General utility applications for securing and tying heavy loads.

Outdoor and industrial applications requiring high strength and weather resistance.

Advantages of Telstra Rope

Superior strength and durability.

Resistant to environmental factors like UV rays and chemicals.

Lightweight yet strong, making it easy to handle.

Ideal for high-load applications in telecom and construction.

High Elasticity & Durability: Nylon ropes have high extended elastic; it is highly durable. They are very resistant to abrasion and are ideal for use in situations where loads and impacts are repeated many times. They, however, absorb water, which can slowly weaken their structure.

Best Uses: Nylon ropes have the best uses in towing, rock climbing, rescue operations, anchor lines and industrial lifting. Bungee jumping and mooring lines, for example, put considerable strain on their ability to stretch and the ability to absorb any sudden loads.

UV Resistant or Minimal Stretch: Unlike nylon, polyester ropes don’t absorb water, have minimal stretch, and are highly UV resistant or weather resistant. However, they are excellent for abrasion resistance and are also strong when wet.

Uses: Polyester ropes are used in boating, sailing, industrial lifting, and rigging applications. For applications especially involving mooring lines in marine or other outdoor applications or pulley systems, there is a preference for minimum stretch.

Polypropylene ropes are lightweight and float on water and are ideal for water-related tasks. The nylon and polyester fibers are more abrasion-resistant, but they are also resistant to chemicals, mildew and moisture. Widely used in water rescue, fishing, electrical work, camping, and general utility purposes:

i) They are inexpensive,

ii) They are commonly found in pool lanes, ski ropes, and temporary fencing because they are resistant to most chemicals.

High Tensile Strength & Heat Resistance: These ropes are five times stronger than steel of the same weight and can endure severe temperatures without weakening. Flames, chemicals and cutting resistance are excellent for high-performance applications.

Common Uses: Kevlar ropes are used extensively in the aerospace, military, high-load lifting, and industrial industries. Extreme durability and heat resistance are also required in paragliding, rescue operations, and in firefighting equipment.

Stronger Than Steel & Low Stretch: Ultra-high molecular weight polyethylene (UHMWPE) ropes like Dyneema and Spectra offer extreme strength with very little stretch. As a result, they’re heavy-duty, lightweight, resistant to abrasion, and will not absorb water.

Applications: UHMWPE ropes are applied in industrial rigging, mountaineering, extreme sports, offshore mooring, and such high-performance marine activities. They also are used in suspension bridges and high-load towing systems because of a high strength-to-weight ratio.

There are ropes, however, that are specialized for specific reasons and have specific traits to satisfy the needs of certain activities. Material, strength, flexibility, and durability, these ropes are ideal for those industries in which climbing, marine, fitness, construction, and survival an applied. The best-specialized rope will not only be the safest but also the most efficient and most productive.

Dynamic vs. Static Ropes: There are dynamic and static ropes. Dynamic ropes stretch under load and they are suited for absorbing impact during falls in mountaineering and rock climbing. Still, static ropes do not stretch, which makes them suitable for rappelling, rescue operations and industrial work.

Safety Considerations: Choosing the right rope according to the use in which it will be used, its diameter and its strength rating is important for ensuring safety. Regularly checking ropes should also be done by climbers to ensure they don’t wear out and consequently compromise safety.

Water-Resistant & Durable: Marine Ropes Are Made to be water-resistant, durable, and withstand saltwater, UV exposure, and harsh weather conditions. They are resistant to decay, mildew and degradation and are appropriate for marine use.

Marine Ropes Types: Dock lines, anchor ropes, and sailing ropes are a few examples of different types of marine ropes. Boats are secured to docks with dock lines, to the anchor with anchor ropes and to the control of sails with sailing ropes (sheets and halyards). The main deciding factors in selecting the right marine rope are the size of the boat, load capacity and water conditions.

Multipurpose & Everyday Use: Utility ropes are lightweight, flexible and almost multi-functional so they can be used for daily use and outdoor purposes. Finally, they are often used for tying, securing, bundling, camping, and other tasks of the same general nature. They aren’t as high-strength as industrial ropes, but they are convenient for quick fixes and general purposes.

Military-Grade Strength: Paracord is an originally military-grade rope (originally used in military applications to tether free-falling parachutes) that is great however you choose to use it as a strong lightweight rope. It is known for its versatility and its durability.

Uses: Paracord is used for uses such as survival situations, outdoor adventures, and emergency repairs. It is also used for making bracelets, tent ropes, fishing lines, and emergency splints. Survivalists and adventurers get it for its ability to hold heavy loads while remaining compact and flexible.

Fitness & Training: Battle ropes are thick, heavy ropes used for strength and endurance training. Thanks to their ability to engage more than one muscle group, they are a good tool for working out athletes and fitness aficionados.

Proper Use & Techniques: Battle ropes are used in high-intensity interval training (HIIT), complete body workouts, or resistance training. These exercises, including wave movements, slams, spirals, etc., increase cardiovascular endurance, core strength, and muscular endurance.

Industrial Applications: Wire ropes consist of steel wire of multiple strands twisted together with maximum strength and durability for industrial use. The ropes are made to withstand extreme loads and can even resist abrasion, one crushing and another at high temperatures.

Applications: Wire ropes are used in suspension bridges, elevators, cranes, in construction, and mining. In addition, they have an important role in industrial applications, lifting, towing and high-load applications. Coated wire ropes are more than suitable for outdoor and marine environments because they have extra protection against corrosion.

Ropes require proper maintenance and care to prevent accidents in which these ropes prolong their life and reliability, and performance. Whether it is a climbing rope, a marine rope, or an industrial rope, regular inspection, cleaning and proper storage are necessary.

1. Cleaning Different Rope Types

Mild detergent and warm water can be used to wash synthetic ropes (nylon, polyester, polypropylene) to remove dirt, salt, or any debris. Fiber is also weakened by harsh chemicals.

For instance, natural fiber ropes such as cotton, manila, sisal, coir should be stored dry, as moisture can cause rot and mold. A damp cloth or dry brush should be used for cleaning.

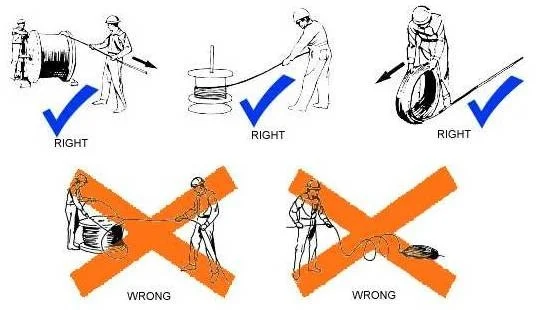

2. Storage Tips

Ropes should be stored in a dry and well ventilated area, not in contact with direct sunlight, chemcials, or in such a way as to be exposed to extreme temperatures.

Properly coil ropes to prevent tangling and kinks of the rope. The shape and use of the rope bag or hanger helps in keeping these articles in shape and preventing wear.

Do not store ropes in damp places, because it will make the natural fiber rope to weaken and grow the mildew on synthetic ropes.

3. Inspection for Wear & Tear

Frayed, cut, or thinning areas should be checked regularly in ropes used in climbing, lifting, and rescue operations.

Check the knots and splices to see that they are secure and not worn out.

Damaged ropes should be replaced immediately as a weak rope can break under load and cause very serious accidents.

Strength & Load Capacity: Consider weight-bearing requirements before choosing a rope.

Flexibility & Water Resistance: Some ropes are better for marine or wet environments.

Natural vs. Synthetic: Natural ropes are biodegradable, while synthetic ropes offer enhanced durability.

Safety Precautions: Always use the appropriate rope for your specific task to avoid failures or accidents.

Selecting the right rope can save or improve safety and efficiency. While natural ropes are eco-friendly they may degrade quicker while synthetic ropes are more durable and weather resistant. HDPE monofilament ropes such as those based on HDPE monofilament, PP baler twine ropes and PP danline rope, and telstra rope are specifically intended for industrial and commercial use. Understand the properties, the strengths, and the best uses for each rope type and you can make wise decisions for each task the safest, longest and most efficient use.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to exports@greplgroup.com

|

Mr. Milanbhai +91 96871 06588 |

|

Mr. Hirenbhai +91 95373 06588 |