Full vs Half Pedestal Wash Basin: Smart Buying Guide

09 January, 2026

Connect With Our Team

Choosing the right rope for a project or task can be overwhelming. With numerous options available in the market, nylon rope and polypropylene rope often top the list for both recreational and industrial uses. Each has its distinct features, advantages, and ideal applications. Understanding these differences will help you make an informed decision for marine, construction, or everyday uses.

Rope is a versatile tool used in various industries, from marine applications to construction and outdoor activities. Among the many types available, nylon rope and polypropylene rope are two of the most popular due to their durability, abrasion resistance, and tensile strength. Choosing the right rope involves assessing key factors like elasticity, moisture absorption, UV resistance, and chemical resistance.

This rope is a synthetic rope known for its extremely strong structure and durable nature. It’s widely used for marine applications, including mooring lines, dock lines, and other industrial rope requirements.

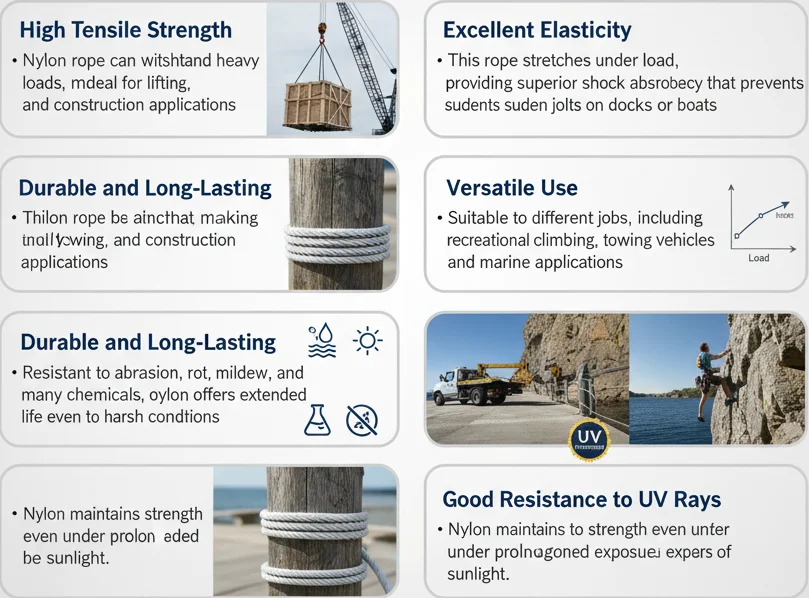

High Tensile Strength: Nylon rope can withstand heavy loads, making it ideal for lifting, towing, and construction applications.

Excellent Elasticity: This rope stretches under load, providing superior shock absorbency that prevents sudden jolts on docks or boats.

Durable and Long-Lasting: Resistant to abrasion, rot, mildew, and many chemicals, nylon rope offers extended life even in harsh conditions.

Versatile Use: Suitable for different jobs, including recreational climbing, towing vehicles, and marine applications.

Good Resistance to UV Rays: Nylon maintains its strength even under prolonged exposure to sunlight.

Shock Absorption: Ideal for mooring and anchor lines.

Strength and Durability: Handles extreme tension without breaking.

Versatile Performance: Works well both on land and in water.

Nylon rope’s elasticity allows it to absorb sudden stress, reducing the risk of snapping. This feature makes it perfect for marine environments, where boats experience movement from waves or sudden wind gusts.

This rope is a lightweight, synthetic rope commonly used for recreational and marine purposes. Unlike nylon, it floats on water, making it ideal for water-related activities. It is also cost-effective, making it suitable for temporary or less demanding tasks.

Lightweight and Floats: This rope is buoyant, making it perfect for water sports, dock lines, and lifelines.

Chemical and Oil Resistance: Offers good protection against chemicals, oils, and mild acids, which makes it practical for industrial uses.

Low Absorption: Does not absorb water, helping it maintain consistent performance in wet conditions.

Durable for Outdoor Use: Resistant to mildew and some UV rays, although less so than nylon.

Affordable and Versatile: Used for tasks like garden work, camping, and temporary rigging in different jobs.

Buoyancy: Floats on water, ideal for marine safety lines.

Low Cost: A budget-friendly option for general-purpose use.

Chemical Resistance: Suitable for environments exposed to mild oils and chemicals.

This Rope is less stretchable, meaning it does not offer the shock absorbency that nylon provides. However, its lightweight and ability to float make it unmatched in water-based applications.

To understand which rope is better, it’s helpful to compare them across several key features:

| Feature | Nylon Rope | Polypropylene Rope |

|---|---|---|

| Tensile Strength | High – suitable for heavy loads | Moderate – adequate for light to medium loads |

| Elasticity | High – absorbs shock and tension | Low – minimal stretch |

| Durability | Very durable, resistant to abrasion, rot, and mildew | Durable, resistant to mildew and chemicals |

| Weight | Heavier | Lightweight, floats on water |

| UV Resistance | Good | Moderate |

| Chemical Resistance | Good | Good |

| Ideal Applications | Marine mooring lines, construction, towing | Marine safety lines, water sports, recreational use |

The decision between nylon rope and polypropylene rope depends on your specific requirements:

You need high stretch strength for heavy lifting or towing.

Your work involves mooring lines or dock lines where shock absorbency is critical.

The rope will be exposed to sunlight radiation, abrasion, or rot-prone environments.

You need a versatile rope for various industries including construction and industrial settings.

You require a rope that floats on water for boating, water sports, or rescue operations.

Cost-effectiveness is a priority, and heavy-duty strength is not required.

You need resistance against chemicals, oil, or other liquids.

The rope is intended for temporary or light-duty applications.

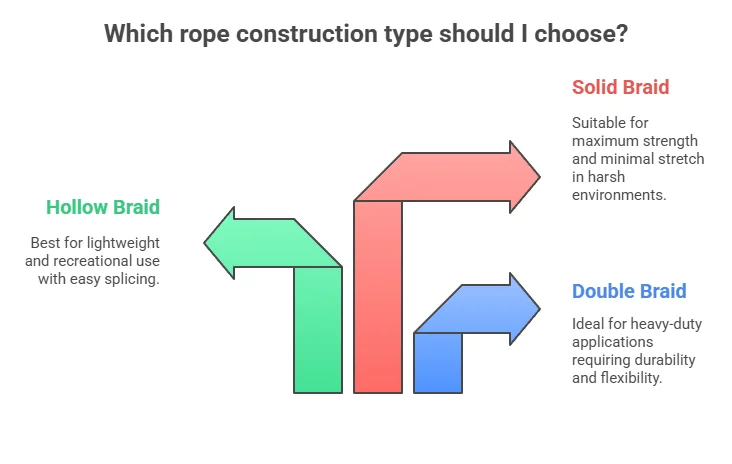

The performance and handling of a rope depend not only on the material but also on its construction type. Understanding the differences helps you select the right rope for your needs.

Double Braid Rope

Double braid rope consists of a strong inner core surrounded by a braided outer cover, combining durability and flexibility. This design provides:

High tensile resilience for heavy-duty applications

Excellent abrasion resistance due to the protective cover

Smooth handling and easy splicing for marine and construction tasks

Applications: Mooring lines, towing, industrial lifting, and anchor lines.

Hollow Braid Rope

Hollow braid rope is woven in a tubular structure without a solid core, making it:

Lightweight and flexible

Easy to splice, knot, or thread through pulleys

Suitable for temporary or recreational applications

Applications: Camping, boating, light-duty marine lines, and decorative purposes.

Solid Braid Rope

Solid braid rope is tightly woven and has no hollow spaces, providing:

Maximum strength and durability

Minimal stretch, making it suitable for static loads

Excellent abrasion resistance in harsh environments

Applications: Construction, heavy-duty industrial rope, dock lines, and permanent rigging.

Both ropes have their place in industrial and recreational settings. For example:

Marine Applications: Nylon is excellent for mooring lines, while polypropylene works well for safety lines or floating barriers.

Construction: Nylon rope’s durability and abrasion resistance make it ideal for lifting heavy materials and industrial tasks.

Outdoor Recreation: Polypropylene’s lightweight and floating nature makes it popular for camping, kayaking, and temporary setups.

Regardless of which rope you choose, proper maintenance can extend its life:

Avoid Prolonged UV Exposure: Store ropes in shaded areas when not in use.

Clean After Use: Rinse with fresh water, especially after marine applications, to remove salt or chemicals.

Inspect for Damage: Check for abrasion, fraying, or mildew before use.

Proper Storage: Coil ropes neatly and keep them dry to prevent rot or mildew growth.

By taking these precautions, you can ensure that both ropes deliver optimal performance for years.

Choosing between nylon rope and polypropylene rope boils down to understanding their resilience, features, and ideal applications. Nylon rope is extremely strong, durable, and offers superior shock absorbency, making it perfect for marine, construction, and heavy-duty tasks. On the other hand, polypropylene rope is lightweight, floats, and is resistant to chemicals, making it ideal for recreational and water-based applications.

Ultimately, selecting the right rope ensures safety, efficiency, and longevity in various applications. By considering tensile durability, elasticity, acid resistance, and intended use, you can choose the rope that best fits your different jobs, whether for marine, industrial, or everyday purposes.

At Grepl Group, we provide both nylon ropes that meet the highest quality standards, ensuring safety, reliability, and performance across diverse industries. By understanding the unique benefits of each material, you can make an informed decision and choose the rope that delivers the best results for your application.

A: Polyester rope is used in marine, construction, and industrial applications due to its resilience, durability, and resistance to ultraviolet radiation.

A: Manila ropes are natural fiber ropes made from the abaca plant, commonly used for decorative purposes or light-duty applications.

A: Polyester rope stretches slightly under load, but less than nylon, offering better dimensional stability for certain applications.

A: Solid braid is tightly woven and durable, hollow braid is lightweight and easy to splice, and double braid combines a strong core with a braided cover for high-performance use.

A: Polypropylene is more UV resistant than nylon, but prolonged exposure to sunlight can still degrade both over time.

A: Yes, solid braid, hollow braid, and double braid ropes can be spliced to create longer lengths or repair damaged sections.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to exports@greplgroup.com

|

Mr. Milanbhai +91 96871 06588 |

|

Mr. Hirenbhai +91 95373 06588 |