Full vs Half Pedestal Wash Basin: Smart Buying Guide

09 January, 2026

Connect With Our Team

When choosing rope for any taskbe it boating, fishing, camping, or general home use, you’ll find several materials in the market. Two of the most popular synthetic types are HDPE monofilament and polypropylene rope. Both look similar at a glance, but their performance, handling, and durability vary significantly depending on where and how you use them.

Let’s break down the differences, benefits, and best applications to help you make the right choice.

Before comparing the two, it helps to understand the types of rope materials available today. Ropes are typically made from either natural fibers like jute, sisal, cotton, or hemp or synthetic fibers, such as nylon, polyester, polyethylene, and polypropylene.

Natural fiber ropes have a rustic charm and good grip, but they absorb water, rot easily, and weaken with time. Synthetic ropes, on the other hand, are lighter, stronger, and resist moisture and mildew.

Among synthetic options, polypropylene (PP rope) and HDPE monofilament ropes are widely used because they balance cost, strength, and versatility. You’ll also find various rope constructions like twisted polypropylene rope, braided polypropylene rope, and 3 strand polypropylene rope, each offering different flexibility, strength, and stretch.

HDPE monofilament stands for High-Density Polyethylene Monofilament, a rope made from a single, strong strand of polyethylene fiber. Unlike multifilament ropes that combine many small fibers, monofilament ropes use thicker individual filaments that provide excellent rigidity and durability.

These ropes are smooth, stiff, and less likely to fray. The monofilament construction means fewer gaps between fibers, so it doesn’t absorb water or trap dirt. That’s why HDPE ropes are common in marine, aquaculture, agriculture, and industrial settings.

HDPE monofilament ropes are often used in trawling, mooring, aquaculture cages, safety nets, and outdoor agricultural setups, where durability and cleanliness matter more than flexibility.

Polypropylene rope often referred to as PP rope or poly rope is one of the most widely used synthetic ropes worldwide. It’s lightweight, strong, and budget-friendly, which makes it a favorite for both household and professional use.

This rope can be made in multiple forms, including twisted polypropylene rope, braided polypropylene rope, or 3 strand polypropylene rope. Each version serves a slightly different need twisted ropes are flexible and easy to handle, while braided ropes are smoother and tangle less.

Polypropylene rope is used for boating, camping, fishing, barrier lines, clotheslines, tarpaulin ties, and general utility purposes. It’s ideal for temporary setups and situations where low cost and lightness matter more than long-term wear resistance.

Here’s a closer look at how these two rope materials differ across key performance factors:

|

Feature |

HDPE Monofilament Rope |

Polypropylene Rope (PP Rope) |

|

Strength & Load Capacity |

High tensile strength and minimal stretch; ideal for industrial and marine use |

Moderate tensile strength; strong enough for general tasks but less suited for heavy lifting |

|

Abrasion Resistance |

Excellent resists rough surfaces and friction |

Moderate outer fibers may fray with continuous rubbing |

|

Flexibility |

Stiffer, harder to knot but holds shape well |

Softer, easy to handle and tie |

|

Water Resistance |

Extremely low absorption; does not get heavy |

Completely waterproof and buoyant |

|

UV & Weather Resistance |

Needs UV stabilizers for prolonged sun exposure |

Also prone to UV degradation but easy to replace |

|

Cost & Availability |

Slightly higher cost; used in specific industries |

Budget-friendly and easily available |

|

Temperature Resistance |

Tolerates slightly higher heat before softening |

Melts at a lower temperature (~165°C) |

|

Appearance & Handling |

Smooth, shiny surface; stays clean longer |

Comes in vibrant colors and comfortable texture |

In short, HDPE monofilament offers toughness and longevity, while polypropylene rope delivers convenience and affordability. Grepl Group, a leading manufacturer and supplier of different types of ropes, offers a wide range of high-quality options including HDPE monofilament, twisted polypropylene rope, braided polypropylene rope, and other rope materials designed to meet diverse industrial, marine, and household needs.

Yes but only in certain situations. HDPE monofilament has better abrasion resistance, chemical durability, and structural stiffness, giving it an edge in heavy-duty or long-term outdoor applications.

However, polypropylene rope is lighter, easier to handle, and strong enough for everyday uses. For example, when setting up a tent, tying a boat, or hanging clothes, polypropylene is more convenient. But if you’re using the rope for mooring lines, industrial pulling, or continuous marine exposure, HDPE monofilament may last much longer.

Yes, it does and that’s one of its biggest advantages. Polypropylene has a lower density than water, which makes it buoyant. This property is especially useful in marine, rescue, and fishing applications because it stays on the surface and is easier to spot.

A yellow polypropylene rope is commonly used for lifelines and water sports for this reason it’s bright, visible, and floats without extra treatment.

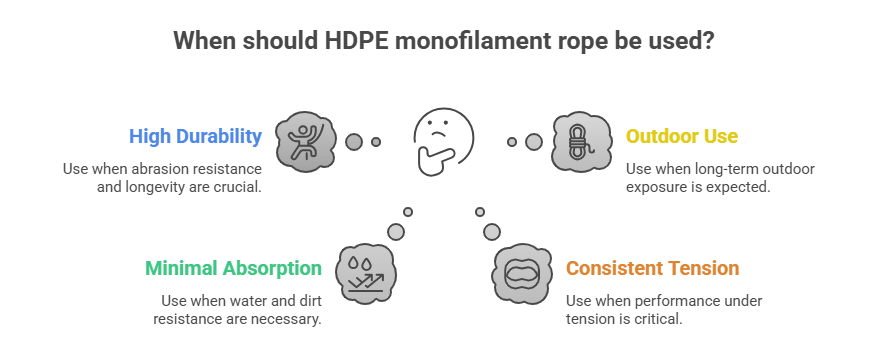

Use HDPE monofilament rope when your application demands:

It’s ideal for marine ropes, fishing nets, agricultural shade net supports, and industrial tie-downs that stay outdoors for long periods.

Choose polypropylene rope when you need:

It’s perfect for general household, construction site markers, sports activities, and agricultural boundaries.

HDPE monofilament rope is made from high-density polyethylene and has a smooth, stiff finish, offering more abrasion resistance and strength. Polypropylene rope, made from PP fibers, is softer, floats on water, and costs less, but it wears faster under heavy friction or sunlight.

2. Is polypropylene rope waterproof?

Yes. Polypropylene is fully waterproof and doesn’t absorb moisture, making it ideal for outdoor and marine use.

It weakens under UV exposure, can melt under high heat, and frays with repeated abrasion. However, it remains one of the most affordable and versatile rope materials available.

Depending on UV exposure and usage, it can last 1–3 years outdoors. Storing it away from direct sunlight extends its life considerably.

Here’s a quick guide to help you decide between hdpe monofilament and polypropylene rope:

|

Use Case |

Recommended Rope Type |

Reason |

|

Boating or water sports |

Polypropylene rope |

Floats easily and is brightly colored |

|

Fishing nets or trawl lines |

HDPE monofilament rope |

Tough, clean, and water-resistant |

|

Camping or general utility |

Polypropylene rope |

Light, flexible, easy to knot |

|

Agriculture or outdoor tie-downs |

HDPE monofilament |

Withstands sun and friction |

|

Temporary setups / DIY tasks |

Polypropylene rope |

Cost-effective and handy |

If you use ropes frequently outdoors, consider buying UV-stabilized versions or storing them in shade to extend lifespan.

Both HDPE monofilament and polypropylene rope are excellent materials, but their ideal uses differ.

Think about where and how you’ll use the rope exposure to sunlight, friction, load capacity, and frequency of use and pick accordingly.

In short, HDPE monofilament is the rope for endurance; polypropylene rope is the rope for convenience.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to exports@greplgroup.com

|

Mr. Milanbhai +91 96871 06588 |

|

Mr. Hirenbhai +91 95373 06588 |